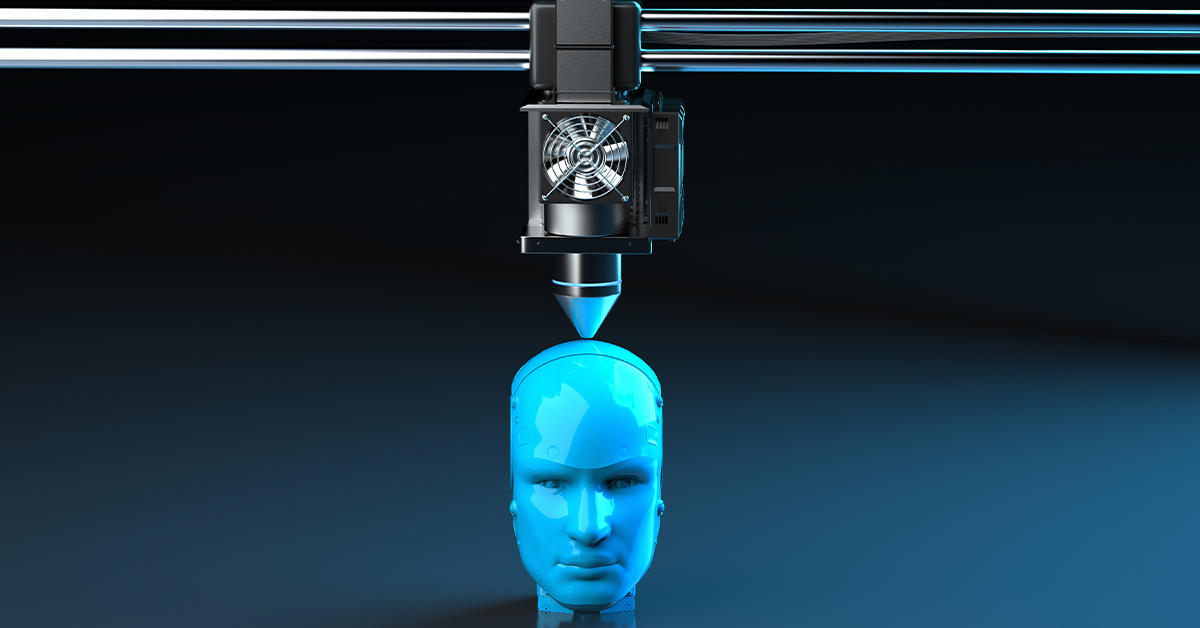

Technology is evolving and transforming to greater heights in all industries. The evolution of design forms for 3D and 4D printing in the construction sector also shows signs of advancement. Nowadays, architects are in demand to create a sustainable environment, and the process comes with various methodologies and innovations. So, the planning college in India understands the need to acknowledge how technology blends with sectors and how students need to develop their skills to begin their career in the architecture field. In this article, you can find a brief explanation of 4D and 3D printing, their processes, and their future applications in the construction field. Let’s discuss further.

What is 4D printing?

The process through which the 3D printed object changes into another structure because of the external energy input is called 4D printing. The external energy can be temperature, light, or any other force. The aerospace, automotive, clothing, construction, healthcare, and other manufacturing industries explore 4D industries.

What is additive manufacturing?

3D printing is the process of creating a three-dimensional item from a digital 3D model or CAD (Computer-Aided Design) data. Due to its capacity to produce stronger, lighter parts and systems, additive manufacturing is considered a comprehensive tool in industrial settings. It provides materials with complex geometries, streamlined production, and enhanced performance.

Process of 4D and 3D Printing Technology:

The top architecture colleges in Tamilnadu focus on covering topics related to construction and the duties of architects in this field. However, students need to learn about the technology currently being used and future innovations that will make a huge revolution. On that list, 4D printing in the construction field has great effect.

3D printing is the process of designing objects by building up materials from one layer to another. With the use of CAD, describe the size, geometry of the objects to be printed, and they are cut into a series of 2D layers to form a 3D object.

4D printing integrates the time component into the 3D objects as a result of its importance in the design process. 4D printing is programmed based on transforming mediums through smart materials that combine material deformations.

So, we can say, the following research and investment in 4D and 3D printing methods are necessary to make improvements in areas like printer structures, materials, and the marketplace.

Five Facts about 4D Printing:

- A new phrase has entered, even though we are still working to comprehend the potential and restrictions of additive manufacturing and three-dimensional printing.

- The only difference between 3D printing and 4D printing is that the latter adds a fourth dimension. This indicates that the printed material will have intrinsic qualities that enable it to change, transform, or move on its own once it is complete.

- The materials used in 4D printing have a direct impact on the final outcome. So-called intelligent materials are solids that, simply because of their fundamental material characteristics, have a feature that changes as they react to external forces or mediums, such as heat, light, humidity, pressure, or magnetic fields.

- This multi material technology boosts the 4D Printing when it has the ability to control and programme materials, from generating concepts to printing shapes that may undergo revolution.

- It can be a promising future when you find the possibilities of building after integrating intelligent materials and 4D printing that adapt to the climate and respond to diverse mediums or forces. We can say that 4D printing with smart materials seems like something you need to rethink.

Future Applications of 4D printing:

- The size of the printer is a limitation for 3D printing furniture, but 4D printing could make it possible to print a flat board that, after being exposed to water or light, will begin to bend up into a chair.

- 4D printing would take the form of pipes in a plumbing system that dynamically alters in diameter depending on the flow rate and water demand. Due to their capacity to adapt to environmental changes, pipes may be able to independently repair themselves if they crack or break.

- The shape-changing capabilities of 4D printed materials may be utilized. They could offer a solution for constructing bridges and shelters since they would construct or repair themselves in the event of weather damage.

- Healthcare, the auto industry, aerospace, and consumer goods are predicted to be the four areas that will use 4D printing technology most extensively.

The additive manufacturing sector has a lot to gain from and clearly benefits from all of the research that has been done so far about the properties of 3D printed materials.You can experiment with the 3D model in the construction field when you’re at an internship while doing your B. Arch degree in the top architect colleges in Coimbatore. Even though 4D printing is still in its early stages, it would be great to see how it will affect the development of additive manufacturing in the future, much like 3D printing did for traditional production.

Hope this guide will be helpful for your career in the construction field.